LineCamera Options

Introducing peripheral components for using Proximity LineCamera as a system.

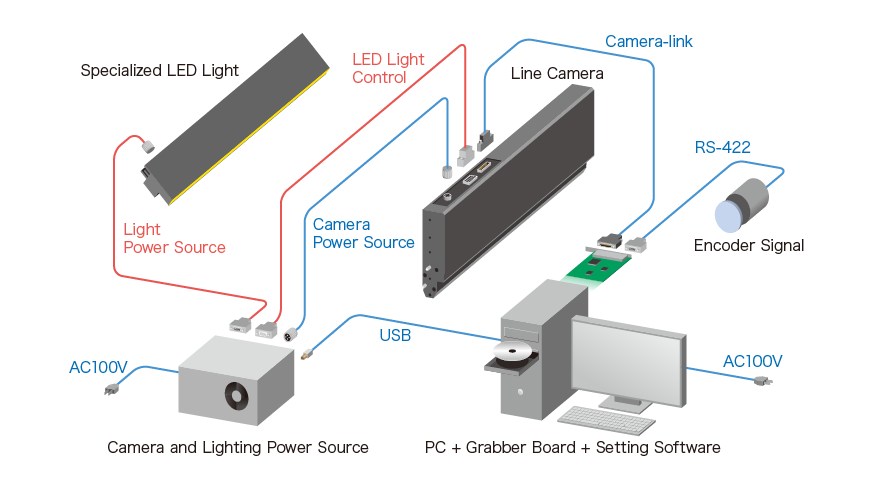

System Configuration

Coretec Proximity LineCamera can capture multiple images with a single scan. The combination of “Specialized LED Light”, “Camera and Lighting Power Source” and “Specialized Cables” makes it possible.

Specialized LED Light

Depending on the lighting arrangement, it can be transmissive lighting, coaxial lighting or oblique lighting. Please specify when ordering.

Camera and Lighting Power Source

Capturing multiple images with high-speed light switching and imaging synchronization

Specialized Cables

Various cables are available.

For details of LineCamera peripherals, see linecamera_peripherals_en_ver1.0.pdf

For details of LineCamera mini peripherals, see linecamera_mini_peripherals_en_ver1.0.pdf

Line Scope

Images from proximity line camera can be displayed on monitor without PC with grabber board.

It can also be used as area camera with camera link connection.