AC Servo Press

The CORETEC Servo Press is an electric press created from our perspective as an equipment manufacturer, and is intended for processes such as parts assembly on automotive production lines, which require traceability, and fabrication/assembly in light electrical appliance industries, which require precision and cleanliness.

This system satisfies Eco Design requirements and appropriately meets the needs of the times, as it is compact, yet provides long service life and high rigidity.

- It is a compact and user-friendly tool.

- It can easily replace a hydraulic press, with no troublesome auxiliary equipment.

- The system can accommodate traceability and Eco Design requirements.

Download Catalog “AC Servo Press”

Download “Servo Press Applications”

Notice for Discontinuation of BS Model Servo Press

Features

Ordinary Electric Press Features

1.Completely electric and thus provides clean environment.

2. Compared to hydraulic, consumes 1/5 amount of electrical power.

3. Can control using stroke, speed, load, and time as parameters.

4. Easily transfers and processes data.

5. Simple equipment configuration is possible, since tool has anti-rotation mechanism.

CORETEC Servo Press Features and Advantages

- Compact

Small pitch allows multi-axis press-fitting.

Multi-axis press-fitting allows fewer processes and saves space.

Reduces cycle time and cost of overall system. - Long life, high rigidity

Adoption of special ball screws enables compactness as well as durability that outperforms the competition. - Real-time control

Immediately stops when problem occurs, limiting damage to workpieces. - Push/pull operation capability (load control)

Built-in load cells allow for control with tensile loads and support for broad range of applications.

Applications

Download “Servo Press Applications”

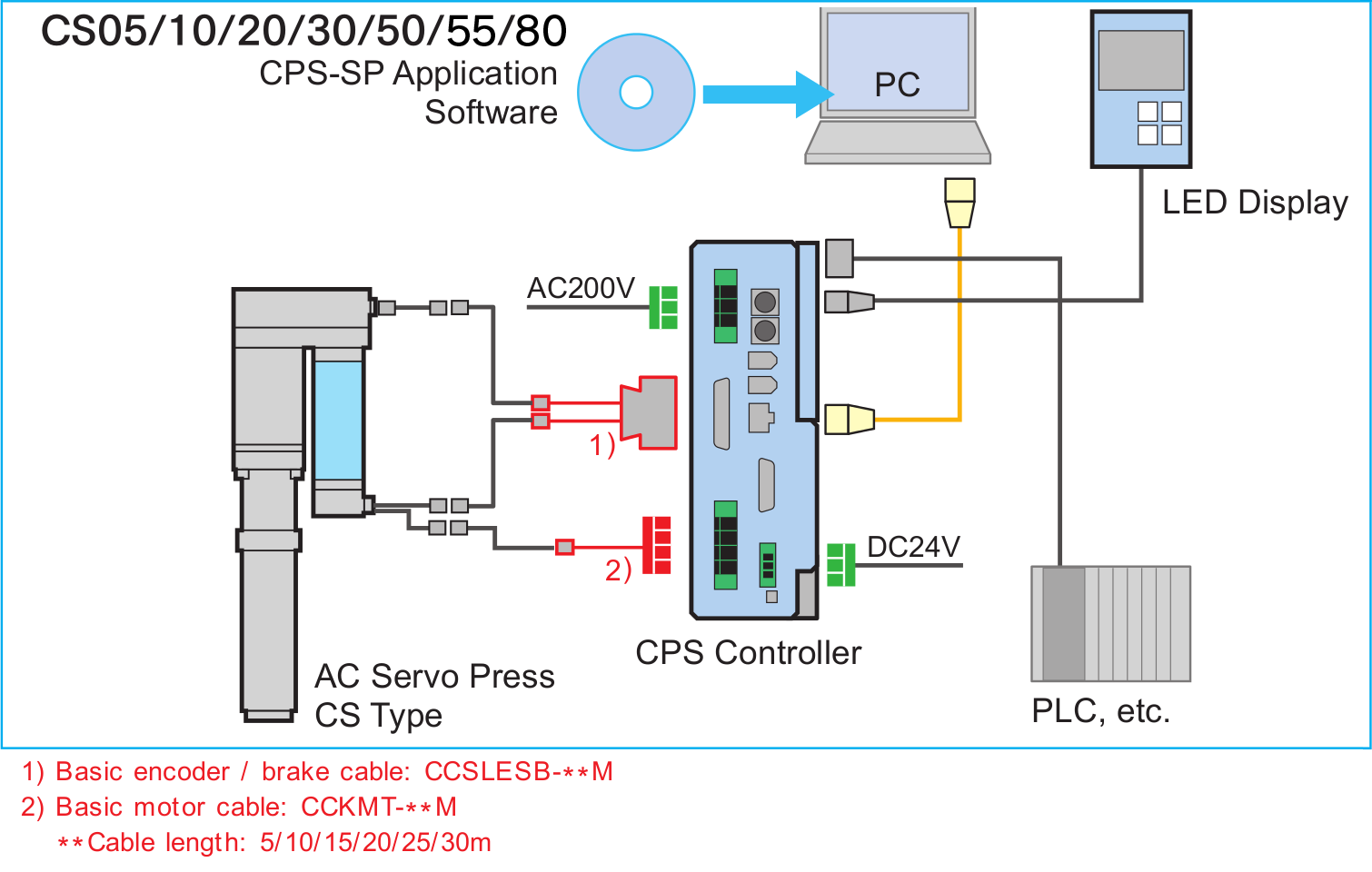

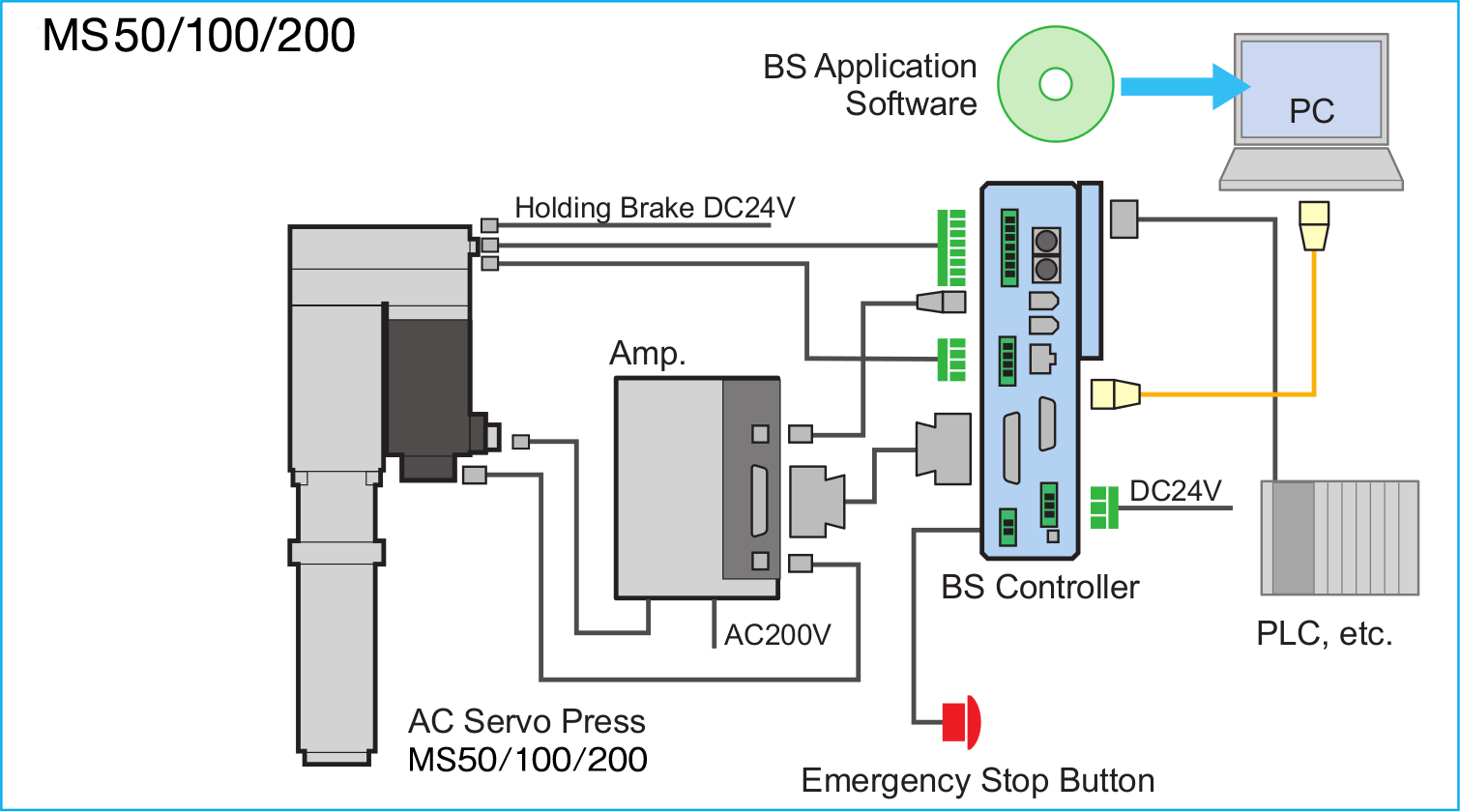

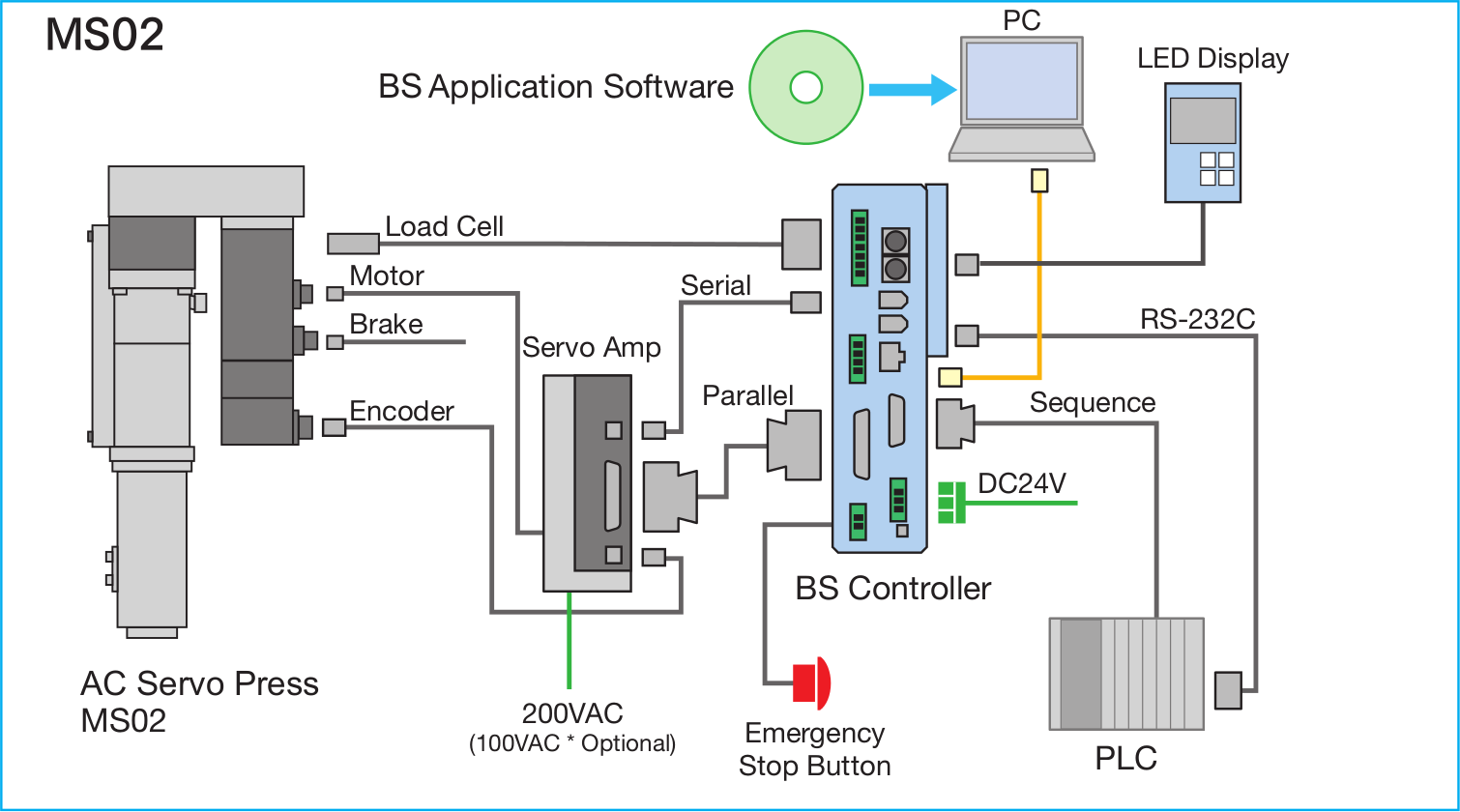

Configuration

Lineup

CS Series – Tool Specifications

| Model | CS05 | CS10 | CS20 | CS30 | CS50 | CS55 | CS80 |

|---|---|---|---|---|---|---|---|

| Position Repeatability | ±0.01mm(under specific conditions) | ||||||

| Max. Stroke | 100/250mm | 100/200/350mm | |||||

| Max. Feed Speed | 300mm/s | 180mm/s | 270mm/s | 240mm/s | 150mm/s | 200mm/s | 130mm/s |

| Instantaneous Maximum Thrust | 5kN | 10kN | 20kN | 30kN | 50kN | 55kN | 80kN |

| Normal Thrust *1 | 3kN | 7kN | 14kN | 21kN | 40kN | 45kN | 70kN |

| Load Cell Accuracy | ±1.5%@ load cell FS | ||||||

| Ambient Temperature | 0-45℃ | ||||||

| Controller | CPS-SP-75** | ||||||

MS Series – Tool Specifications (MS50/MS100/MS200)

| Model | MS50 | MS100 | MS200 |

|---|---|---|---|

| Position Repeatability | ±0.01mm(under specific conditions) | ||

| Max. Stroke | 100/200/350mm | 100/200mm | |

| Max. Feed Speed | 250mm/s | 150mm/s | 110mm/s |

| Instantaneous Maximum Thrust | 50kN | 100kN | 200kN |

| Normal Thrust *1 | 45kN | 70kN | 150kN |

| Load Cell Accuracy | ±1.5%@ load cell FS | ||

| Ambient Temperature | 0-45℃ | ||

| Controller | BS-M3A-** | ||

MS Series – Tool Specifications (MS02)

| Model | MS02-100B |

|---|---|

| Position Repeatability | ±0.01mm(under specific conditions) |

| Max. Stroke | 100mm |

| Max. Feed Speed | 225mm/s |

| Instantaneous Maximum Thrust | 2kN |

| Normal Thrust *1 | 1.5kN |

| Load Cell Accuracy | ±1.5%@ load cell FS |

| Ambient Temperature | 0-45℃ |

| Controller | BS-M3A-** |

*1 This is the applicable thrust that takes mechanical life into account.

These specifications are subject to change without prior notification.

For the latest information, contact our representative.

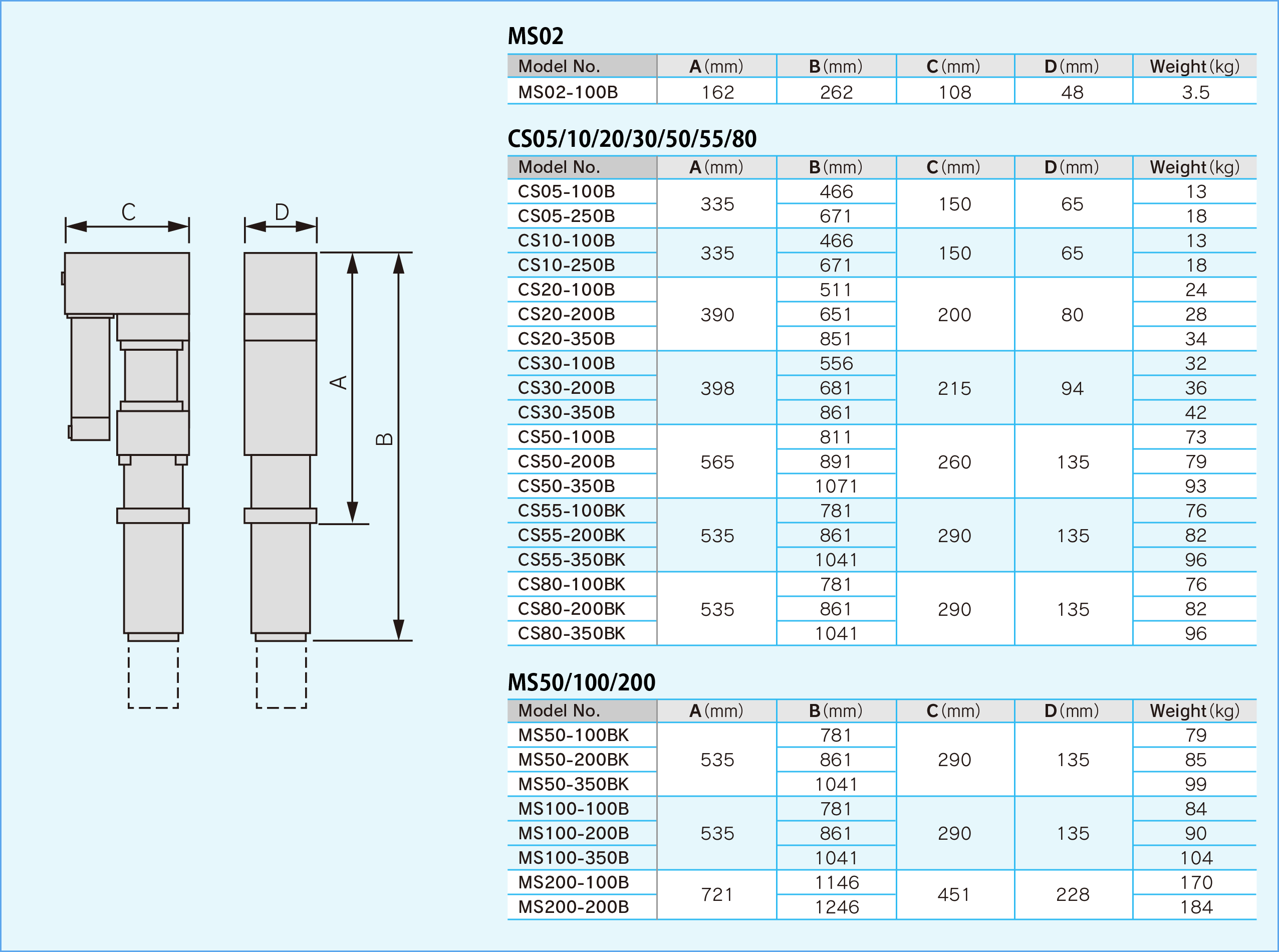

Tool Dimensions

※If you would like CAD drawings (DXF data), go to the Contact Us page.

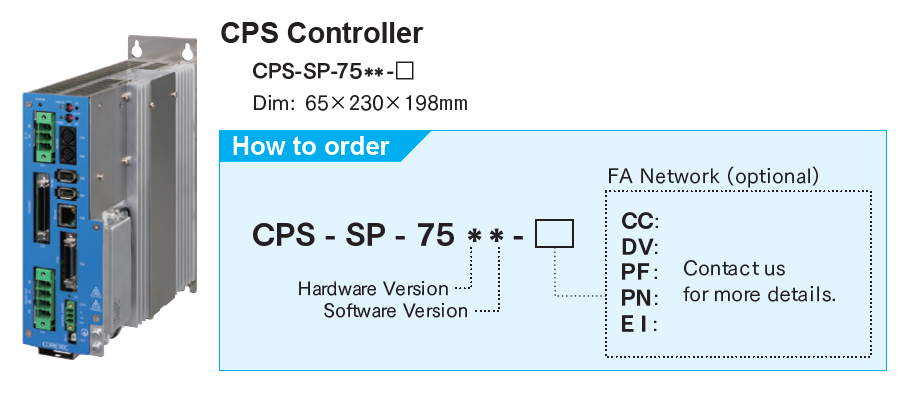

Controller

Through maturation, the experience and technology accumulated with the IPS have been regenerated in the CPS controller.

The controller inherits not only the tool asset but our unique programming system.

The previous functions have been further polished, making the finished system easier to use.

CPS Controller Specifications

| Item | Detail | |

|---|---|---|

| Appearance | See External Dimensions. | |

| Ambient Conditions | Temperature | 0-50℃ |

| Humidity | 85% or less (no condensation) | |

| Elevation | 1,000 m or less | |

| Installation Location | Not allowed to be installed in harmful environment subject to corrosive gas, cutting oil, metal powder, oil, etc. | |

| Control Power Supply | DC24V±10% | |

| Power Consumption of Control Power Supply [W] | 6 | |

| Installation Method | Back panel installation | |

| Seismic Resistance | 0.5 G (10-50 Hz) | |

| Impact Resistance | 5G | |

| Serial Communication RS-485 | 115.2 kbps servo amp exclusive | |

| Serial Communication RS-232C | 19.2 to 76.8 kbps dedicated protocol | |

| Ethernet | UDP/IP Static IP address | |

| Load Cell Accuracy | ±1.5%@ load cell full scale | |

| Load Sensor Resolution | 12 bit | |

| Input Signal | Start, reset, program selection, user input bit, etc. | |

| Output Signal | Ready, operation in progress, judgment, alarm, user output bit, etc. | |

| Status Indicator | 4 dedicated LEDs | |

| Cable Length | Max. 30 m | |

| Execution Programs | 31 programs | |

| Execution Result Saving Function | 4,000 results | |

* These specifications are subject to change without prior notification.

For the latest information, contact our representative.

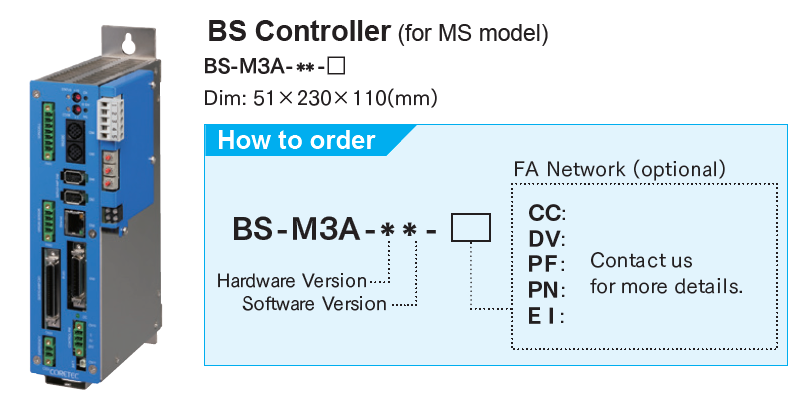

BS Controller Specifications

| Item | Detail | |

|---|---|---|

| Appearance | See External Dimensions. | |

| Ambient Conditions | Temperature | 0-50℃ |

| Humidity | 85% or less (no condensation) | |

| Elevation | 1,000 m or less | |

| Installation Location | Not allowed to be installed in harmful environment subject to corrosive gas, cutting oil, metal powder, oil, etc. | |

| Control Power Supply | DC24V±10% | |

| Power Consumption of Control Power Supply [W] | 6 | |

| Installation Method | Back panel installation | |

| Seismic Resistance | 0.5 G (10-50 Hz) | |

| Impact Resistance | 5G | |

| Serial Communication RS-485 | 115.2 kbps servo amp exclusive | |

| Serial Communication RS-232C | 19.2 to 76.8 kbps dedicated protocol | |

| Ethernet | UDP/IP Static IP address | |

| Load Cell Accuracy | ±1.5%@ load cell full scale | |

| Load Sensor Resolution | 12 bit | |

| Input Signal | Start, reset, program selection, user input bit, etc. | |

| Output Signal | Ready, operation in progress, judgment, alarm, user output bit, etc. | |

| Status Indicator | 4 dedicated LEDs | |

| Cable Length | Max. 30 m | |

| Execution Programs | 31 programs | |

| Execution Result Saving Function | 4,000 results | |

* These specifications are subject to change without prior notification.

For the latest information, contact our representative.

External Dimensions

CPS-SP-75**

BS-M3A-**

※If you would like CAD drawings (DXF data), go to the Contact Us page.

Software

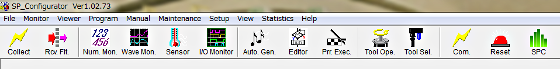

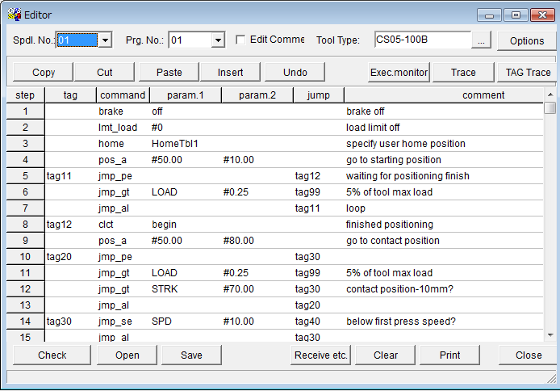

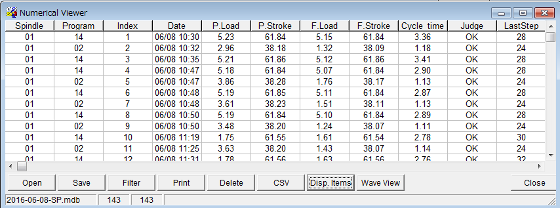

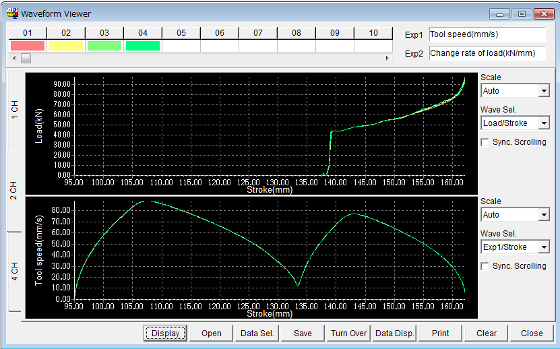

The CPS SP Configurator application software supports not only CPS environment setup and program creation but the display and saving of press-fitting result data as well as various types of monitoring.

Supported OS: Windows 10/8.1/7/Vista/XP/2000 (64bit / 32bit)

Main Menu

Editor

Numeric Monitor

Waveform Monitor

Option

AC Servo Press Options

Electromagnetic Brake

This brake stops the ram’s free fall when the servo is OFF.

It is not used for normal braking or damping.

If this option is needed, please notify our sales representative when making a tool purchase.

Special Display Device

This dedicated display device shows the results of press fitting.

It can also monitor things such as alarm codes and controller-specific information.

Just connect to an RS-232C port and use.

For details, ask our sales representative.

Data Collection Software

This personal computer application can combine and store press fitting data (waveform and numeric), as well as product number and location (press fit location) information.

It is unnecessary to install dedicated boards and drivers, so a special PC is also not required.

It is effective with equipment that requires traceability.

For details, ask our sales representative.