AC SERVO NUTRUNNER

CORETEC nutrunners are servo nutrunners created from our perspective as an equipment manufacturer, and are intended for processes such as part fastening on automotive production lines, which require traceability, and fabrication/assembly in light electrical appliance industries, which require precision and cleanliness.

This system satisfies Eco Design requirements and appropriately meets the needs of the times, as it is compact, yet provides long service life and high rigidity.

- Has light and slim body.

- With a highly flexible programming system, it flexibly supports a wide variety of fastening methods.

- Users can be confident that it meets modern requirements for quality control.

Features

Tool

- Equipped with high-speed, high-output, low-inertia motor and lightweight gears designed specially for a nutrunner, reduces rotational inertia. Contributes to improved fastening accuracy.

- Adopts inner type structure for strength against external disturbances.

- Has rich lineup of offset gear, angle head, cube-type, and special gear models.

Program

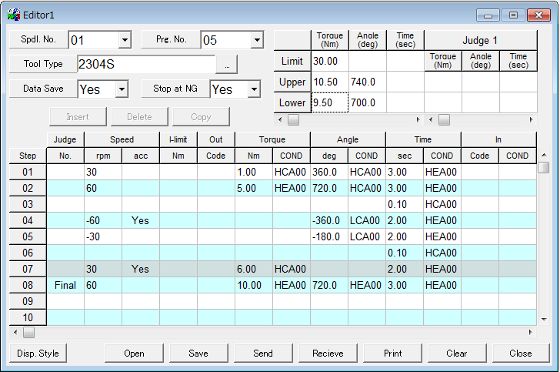

- Highly flexible program system.

A program can contain up to 32 steps. The operation conditions (speed, current limit, external output) and branch conditions (torque, angle, time, external input, and torque rate) are set for each step. - Adds branch function to desired steps. Loop configuration is also completely flexible.

- Expands determination function. In addition to the conventional final determination, it is possible to determine the torque, angle, and time in 3 arbitrary locations.

- Parameters in a program can be rewritten from the PLC. Has unheard-of potential that surpasses simple multiproduct support.

Controller

- Tool assets have been retained, and it is also possible to drive all of the tools of the former IPS models.

- Comes standardly equipped with Ethernet, and provides satisfying operational response and rapid data acquisition.

- Supports various FA networks.

- A one-unit controller supports all tool models.

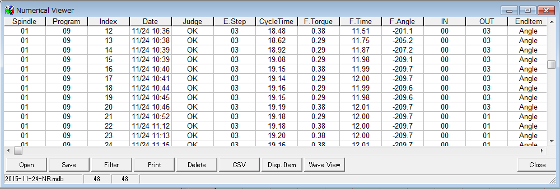

Result Data

- Fastening result, product name, seal number, etc., are linked in controller. Traceability support is also thorough.

- Latest 2700 data are always stored in controller unit.

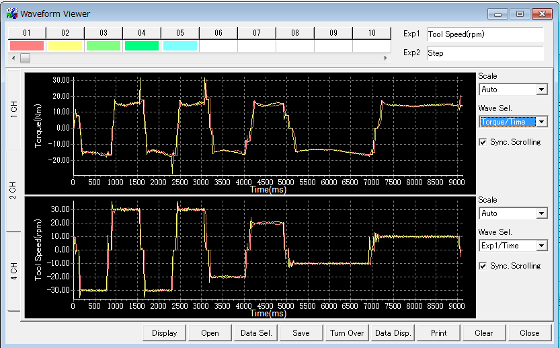

- Application software can display result data and fastening waveform data, and save and print data.

- Enhanced monitor function. Waveforms also displayed for tool speed, torque rate, etc. Cycle time is also easily shortened by simple operation (motion) analysis.

Applications

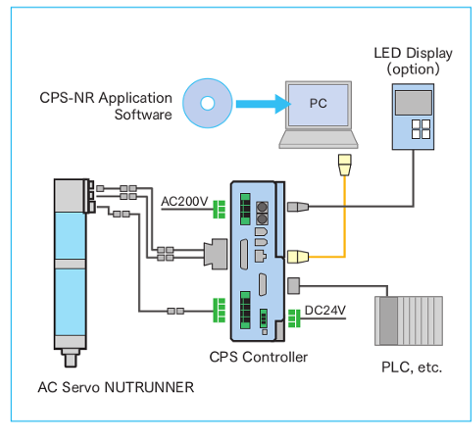

Configuration

Lineup

| Classification | Model | Max RPM |

Torque Range | Max Tool Torque |

Max Tool RPM |

Tool Weight |

||

|---|---|---|---|---|---|---|---|---|

| (rpm) | (Nm) | (Nm) | (rpm) | (Kg) | ||||

【Straight Model】 |

2301S | 1080 | 2 | ~ | 6 | 6.3 | 1350 | Approx. 1.8 |

| 2302S | 540 | 5 | ~ | 22 | 22 | 670 | Approx. 1.9 |

|

| 2304S | 250 | 12 | ~ | 34 | 40 | 310 | Approx. 1.9 |

|

| 2505S | 610 | 19 | ~ | 56 | 65 | 760 | Approx. 5.5 |

|

| 2509S | 285 | 33 | ~ | 94 | 110 | 350 | Approx. 5.5 |

|

| 2510S | 490 | 24 | ~ | 68 | 80 | 610 | Approx. 5.7 |

|

| 2515S | 285 | 42 | ~ | 120 | 140 | 350 | Approx. 5.5 |

|

| 2520S | 230 | 57 | ~ | 162 | 190 | 290 | Approx. 5.7 |

|

| 2620S | 240 | 63 | ~ | 179 | 210 | 300 | Approx. 9 |

|

| 2630S | 170 | 93 | ~ | 264 | 303 | 220 | Approx. 9 |

|

| 2907S6W *1 | 89 | 186 | ~ | 527 | 612 | 110 | Approx. 20 |

|

| 2915S6W *1 | 50 | 330 | ~ | 750 | 1100 | 60 | Approx. 20 |

|

【Cube Model】 |

2402Q | 410 | 6 | ~ | 17 | 20 | 510 | Approx. 3.3 |

| 2405Q | 190 | 16 | ~ | 47 | 55 | 240 | Approx. 3.3 |

|

| 2610Q *1 | 480 | 30 | ~ | 85 | 100 | 590 | Approx. 9.5 |

|

| 2620Q | 240 | 63 | ~ | 180 | 210 | 300 | Approx. 9.5 |

|

| 2630Q | 170 | 90 | ~ | 255 | 300 | 220 | Approx. 9.5 |

|

| 2650Q *1 | 100 | 141 | ~ | 400 | 470 | 130 | Approx. 13 |

|

【Angle Head Model】 |

2302S-A12 | 345 | 10 | ~ | 30 | 31 | 430 | Approx. 3.8 |

| 2304S-A12 | 160 | 14 | ~ | 36 | 38 | 200 | Approx. 3.8 |

|

| 2302S-A13 | 290 | 13 | ~ | 38 | 45 | 360 | Approx. 3.9 |

|

| 2304S-A13 | 136 | 19 | ~ | 56 | 65 | 170 | Approx. 3.9 |

|

| 2402Q-A12 | 260 | 9 | ~ | 26 | 30 | 330 | Approx. 5.2 |

|

| 2402Q-A13 | 147 | 12 | ~ | 34 | 40 | 180 | Approx. 5.2 |

|

| 2405Q-A13 | 68 | 25 | ~ | 73 | 85 | 80 | Approx. 5.2 |

|

| 2505S-A13 | 320 | 36 | ~ | 102 | 120 | 410 | Approx. 7.5 |

|

| 2509S-A13 | 150 | 40 | ~ | 110 | 135 | 190 | Approx. 7.5 |

|

| 2510S-A13 | 270 | 40 | ~ | 110 | 135 | 330 | Approx. 7.7 |

|

| 2510S-A18 | 370 | 30 | ~ | 91 | 106 | 460 | Approx. 11.7 |

|

| 2515S-A18 | 210 | 54 | ~ | 153 | 180 | 260 | Approx. 10.5 |

|

| 2520S-A18 | 180 | 72 | ~ | 200 | 240 | 220 | Approx. 11.7 |

|

| 2520S-A20 | 100 | 126 | ~ | 357 | 409 | 130 | Approx. 12.5 |

|

| 2620S-A18 | 180 | 75 | ~ | 200 | 250 | 230 | Approx. 14.8 |

|

| 2620S-A20 | 120 | 135 | ~ | 383 | 450 | 150 | Approx. 15.5 |

|

| 2630S-A20 | 80 | 142 | ~ | 400 | 475 | 100 | Approx. 15.5 |

|

| 2610Q-A13 *1 | 260 | 40 | ~ | 110 | 135 | 320 | Approx. 11.5 |

|

| 2620Q-A18 | 180 | 75 | ~ | 200 | 250 | 230 | Approx. 15.1 |

|

| 2620Q-A20 | 120 | 135 | ~ | 383 | 439 | 150 | Approx. 16 |

|

| 2630Q-A20 | 80 | 142 | ~ | 400 | 475 | 100 | Approx. 16 |

|

【Offset Model】 |

2302S-F300A | 540 | 7 | ~ | 21 | 21 | 670 | Approx. 3.2 |

| 2302S-F314A *1 | 375 | 11 | ~ | 30 | 30 | 470 | Approx. 3.4 |

|

| 2304S-F300A | 255 | 12 | ~ | 34 | 40 | 310 | Approx. 3.2 |

|

| 2304S-F314B *1 | 175 | 16 | ~ | 48 | 56 | 220 | Approx. 3.4 |

|

| 2402Q-F300B | 410 | 6 | ~ | 17 | 20 | 510 | Approx. 3.5 |

|

| 2405Q-F300B | 190 | 14 | ~ | 40 | 47 | 240 | Approx. 3.5 |

|

| 2405Q-F314C *1 | 130 | 23 | ~ | 68 | 79 | 160 | Approx. 3.7 |

|

| 2505S-F400BA *1 | 610 | 19 | ~ | 56 | 65 | 760 | Approx. 7.2 |

|

| 2505S-F412BA *1 | 480 | 25 | ~ | 73 | 85 | 600 | Approx. 7.2 |

|

| 2509S-F3400A *1 | 285 | 35 | ~ | 102 | 119 | 350 | Approx. 7.2 |

|

| 2509S-F400BA *1 | 285 | 33 | ~ | 94 | 110 | 350 | Approx. 7.2 |

|

| 2509S-F412BA *1 | 225 | 40 | ~ | 115 | 135 | 280 | Approx. 7.2 |

|

| 2510S-F3400B *1 | 490 | 24 | ~ | 68 | 80 | 620 | Approx. 7.4 |

|

| 2510S-F400BC *1 | 490 | 24 | ~ | 68 | 80 | 620 | Approx. 7.4 |

|

| 2510S-F412BB *1 | 390 | 28 | ~ | 81 | 95 | 490 | Approx. 7.4 |

|

| 2520S-F600 | 230 | 57 | ~ | 162 | 190 | 290 | Approx. 8.2 |

|

| 2520S-F619A | 120 | 102 | ~ | 289 | 360 | 150 | Approx. 8.2 |

|

| 2620Q-F4003 *1 | 240 | 43 | ~ | 125 | 146 | 300 | Approx. 13.3 |

|

| 2620Q-F619A | 130 | 102 | ~ | 289 | 340 | 160 | Approx. 12 |

|

| 2620S-F600 | 240 | 60 | ~ | 170 | 200 | 300 | Approx. 11.5 |

|

| 2620S-F619A | 130 | 102 | ~ | 289 | 340 | 160 | Approx. 11.5 |

|

| 2630Q-F619A | 90 | 102 | ~ | 289 | 340 | 120 | Approx. 12 |

|

| 2630S-F600 | 170 | 93 | ~ | 170 | 292 | 220 | Approx. 11.5 |

|

| 2630S-F619A | 90 | 102 | ~ | 289 | 340 | 120 | Approx. 11.5 |

|

Special Notes

- The applicable range contains values that apply to use with general fastening. Usage outside this range may be possible depending on the environment and use conditions.

- Tools conforming to Underwriters Laboratories (UL) standards have different specifications for lead cables and connectors.

- These specifications are subject to change without prior notification.

For the latest information and details, contact our representative.

*1) Delivery dates will be discussed with the customer separately.

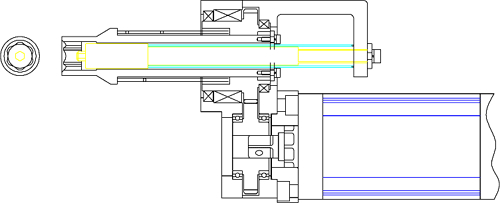

Tool Dimensions

* If you would like CAD drawings (DXF data), go to the Contact Us page.

Straight Type (Standard)

Straight Type

#23**S

#25**S

(2505・2509)

(2515)

(2510・2520)

#26**S

#29**S

(2907)

(2915)

Cube Type

#24**Q

#26**Q

Angle Head Type

#23**S・24**Q-A12

#23**S・2400Q-A13

#2505S・2509S-A13

#2515S・2610Q-A13

#25**S・26**S・26**Q-A18

#25**S・26**S・26**Q-A20

#23**S・24**Q-A12

#23**S・2400Q-A13

#2505S・2509S-A13

#2515S・2610Q-A13

#25**S・26**S・26**Q-A18

#25**S・26**S・26**Q-A20

#23**S・24**Q-A12

#23**S・2400Q-A13

#2505S・2509S-A13

#2515S・2610Q-A13

#25**S・26**S・26**Q-A18

#25**S・26**S・26**Q-A20

Offset Type

#2302S/2304S-F300A

#2402Q/2405Q-F300B

#2302S-F314A

#2304S/2402Q/2405Q-F314B/C

#2505S/2509S-F400BA

#2510S-F400BC

#2505S/2509S/2510S-F412BA/BB

#2509S/2510S-F3400A/B

#2520S/2620S/2630S-F600

#2520S/2620S/2630S/2620Q/2630Q-F619A

#2620S/-F4003

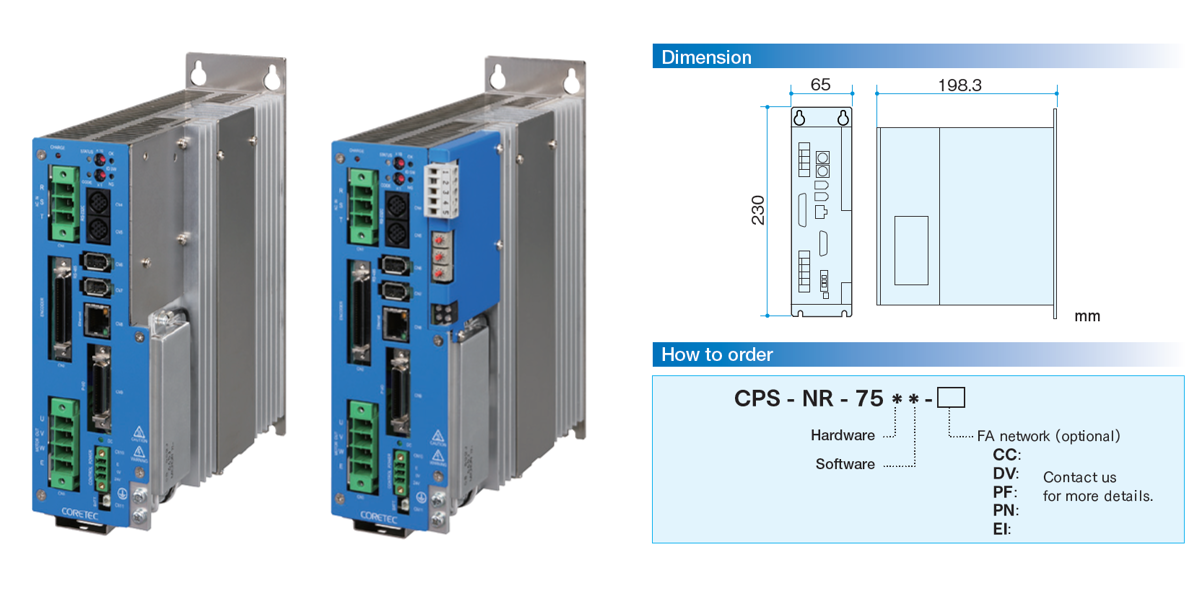

Controller

Through maturation, the experience and technology accumulated with the IPS have been regenerated in the CPS controller.

The controller inherits not only the tool asset but our unique programming system.

The previous functions have been further polished, making the finished system easier to use.

* If you would like CAD drawings (DXF data), go to the Contact Us page.

CPS Controller Specifications

| Item | Detail | |

|---|---|---|

| Appearance | See External Dimensions. | |

| Ambient Conditions | Temperature | 0~50℃ |

| Humidity | 85% or less (no condensation) | |

| Elevation | 1,000 m or less | |

| Installation Location | Not allowed to be installed in harmful environment subject to corrosive gas, cutting oil, metal powder, oil, etc. | |

| Power Supply | 3-phase or single-phase AC100-230 V±10%, 50/60 Hz | |

| Grounding | Class D grounding construction | |

| Control Power Supply | DC24V±10% | |

| Power Consumption of Control Power Supply [W] | 15 | |

| Cooling System | Forced air cooling | |

| Installation Method | Back panel installation | |

| Seismic Resistance | 0.5G(10~50Hz) | |

| Impact Resistance | 5G | |

| Control Method | Semiclosed loop via encoder feedback | |

| Serial Communication RS-485 | 19.2 to 76.8 kbps dedicated protocol, multidrop connection | |

| Serial Communication RS-232C RS-232C |

19.2 to 76.8 kbps dedicated protocol | |

| Ethernet | UDP/IP Static IP address | |

| Torque Sensor Resolution | 12 bit | |

| Input Signal | Start, reset, program selection, user input bit, etc. | |

| Output Signal | Ready, operation in progress, judgment, alarm, user output bit, etc. | |

| Status Indicator | 4 dedicated LEDs | |

| Cable Length | Max. 30 m | |

| Execution Programs | 31 programs | |

| Execution Result Saving Function | 2,700 results | |

Master Controller Specifications

| Item | Detail | |

|---|---|---|

| Appearance | See External Dimensions. | |

| Ambient Conditions | Temperature | 0~50℃ |

| Humidity | 85% or less (no condensation) | |

| Elevation | 1,000 m or less | |

| Installation Location | Not allowed to be installed in harmful environment subject to corrosive gas, cutting oil, metal powder, oil, etc. | |

| Control Power Supply | DC24V±10% | |

| Power Consumption of Control Power Supply [W] | 6 | |

| Installation Method | Back panel installation | |

| Seismic Resistance | 0.5 G (10-50 Hz) | |

| Impact Resistance | 5G | |

| Serial Communication RS-485 |

19.2 to 76.8 kbps axis controller control dedicated | |

| Serial Communication RS-232C |

19.2 to 76.8 kbps dedicated protocol | |

| Ethernet | UDP/IP Static IP address | |

| Input Signal | Start, reset, program selection, user input bit, etc. | |

| Output Signal | Ready, operation in progress, judgment, alarm, user output bit, etc. | |

| Status Indicator | 4 dedicated LEDs | |

| Cable Length | Max. 30 m | |

| Execution Programs | 31 programs | |

| Execution Result Saving Function | 2,000 results | |

* These specifications are subject to change without prior notification.

For the latest information, contact our representative.

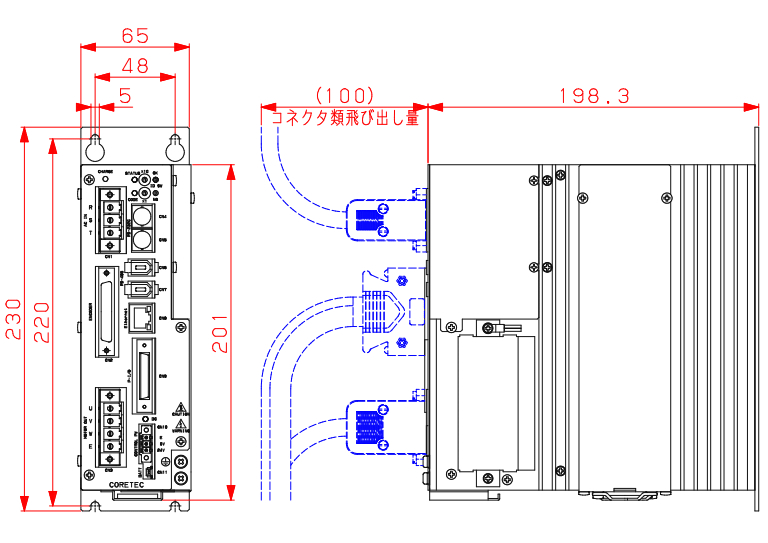

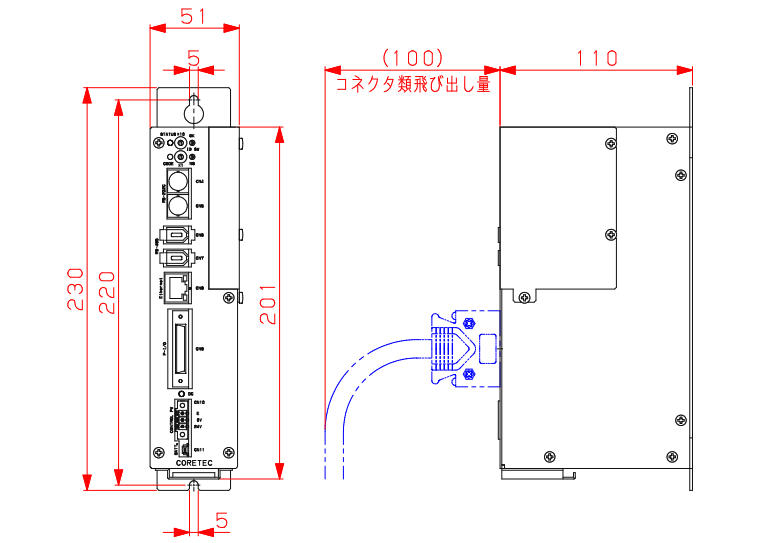

External Dimensions

Axis Controller CPS-NR-75**

Master Controller MA-CN-1A

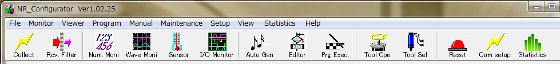

Software

The CPS NR Configurator application software supports not only CPS environment setup and program creation but the display and saving of fastening result data as well as various types of monitors.

Supported OS: Windows 10/8.1/7/Vista/XP/2000 (64bit / 32bit)

Main Menu

Editor

Numeric Monitor

Waveform Monitor

Option

Options for AC Servo Nutrunner

Slide Joint

Slide joints used as nutrunner end attachments are introduced here.

Slide joints, quick joints, and socket adapters in a wide variety of sizes are available.

Download Catalog “Slide Joints”

Special Gears

To be able to fasten a variety of structural objects, CORETEC designs and manufactures special attachments and gears. For details, consult with our sales representative.